Robotics Revolution. Right now, two-legged robots are stepping out of the lab and into the real world, ready to take their place alongside us.

They’re no longer just novelty prototypes for trade shows; they’re sophisticated machines that can confidently climb stairs, maintain their balance on uneven terrain, and perform tasks where wheeled machines would fail.

You’re likely already familiar with two prominent examples: Boston Dynamics’ Atlas and Tesla’s Optimus.

Robotics Revolution and Tesla.

The world got a glimpse of this future at Tesla AI Day 2022, where the first prototype of the Optimus robot made its public debut. The stripped-down machine, moving slowly on its two legs, walked onto the stage, waved to the crowd, and performed a simple dance.

According to Elon Musk, it was the first time the prototype had moved without any external assistance. After its brief performance, the robot independently walked off stage.

Further details on Optimus’s capabilities were shown in a separate video a clear indication that the company wasn’t willing to risk a live demonstration of complex tasks.

The video showcased the robot’s ability to carry boxes and water plants using its built-in sensors. Company representatives have since stated that Optimus robots are already at work in Tesla factories, performing routine tasks like moving car body parts, all under human supervision.

So, why are experts so confident that these two-legged machines are the key to the future of robotics? The answer lies in a combination of efficiency, reliability, and sheer practicality.

The Economic Advantage of Bipedal Motion.

The logic is simple, and nature has already proven it: walking on two legs is the most energy-efficient way to move across the ground. Humans expend a minimal amount of energy for walking, and modern robots, like Agility Robotics’ CASSIE, are getting closer to matching this level of efficiency.

For comparison, six-legged machines are massive energy consumers, devouring dozens of times more power than their bipedal counterparts.

This makes them expensive “electricity gourmands” that are simply not sustainable for large-scale operation. The energy savings alone make bipedal design a clear winner.

Unparalleled Reliability and Simplicity.

It’s not just about battery life. The more moving parts a robot has, the higher the probability of failure. A two-legged robot has around a dozen actuators, giving it a system reliability of approximately 78%.

A six-legged robot, with its many additional joints, has a reliability of less than 70%. When you scale production to hundreds of thousands of units, this difference translates into billions of dollars in savings on repairs and maintenance.

In this case, it’s not just the romantic notion of “humanoid walking machines” that wins it’s cold, hard math.

Computational Efficiency and Ease of Control.

There’s also a significant computational side to the argument. The more limbs a robot has, the more complex its control system becomes.

The algorithms for a six-legged robot require several times more processing power, which means you either have to sacrifice reaction speed or install expensive, high-end electronics.

Bipedal systems are simpler, easier to optimize, and allow engineers to release new, improved versions much faster. This is precisely why companies like Tesla and Agility Robotics are placing their bets on bipedal models.

Adapting to a World Built for Humans.

We can’t forget about infrastructure. Our cities are built for people. Standard staircases, doorways, and narrow hallways are designed for a 15-20 cm stride and a shoulder width of about 80 cm.

A two-legged robot feels right at home in these environments, maintaining up to 90% of its efficiency.

Multi-legged platforms, however, are forced to expend three to four times more energy and often get stuck in tight spaces, much like trying to squeeze a large piece of furniture through a narrow door.

The conclusion is clear.

The bipedal robots aren’t just more familiar in appearance; they are objectively more economical, more reliable, and better suited to our world.

Their development is becoming cheaper, and mass production promises to lower their price to the level of affordable consumer electronics.

The question is no longer whether they will appear on our streets and in our factories, but how soon. That is certainly good, but what about safety?

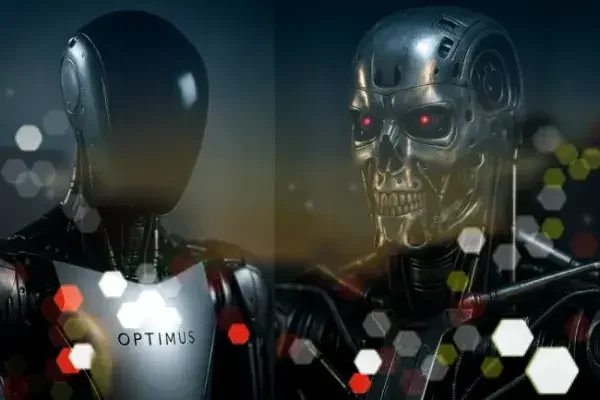

The Challenge of Robot Control and Safety

The fear of dangerous robots is a common theme in science fiction, and it’s a valid concern for real-world applications. The risk isn’t just about a robot suddenly “turning evil.”

It’s more about potential malfunctions, programming errors, or unforeseen circumstances that could lead to a robot harming a person or causing damage.

For example, a robot designed to assist in a factory could malfunction and apply too much force, or a household robot could misinterpret a command and cause an accident. The core challenge is building systems that are not only capable but also fail-safe and predictable, even in complex, uncontrolled environments.

The Solutions.

Layers of Control and Safety.

To prevent robots from becoming dangerous, the robotics community is focusing on a multi-layered approach to control and safety.

Hardware Safeguards: This is the first line of defense. Robots are being built with physical safety features. This includes an emergency stop (E-stop) button that can be easily accessed by a human to immediately shut the robot down.

Many industrial robots also have force and torque sensors that can detect if they are applying too much pressure or if they have come into contact with something unexpected, like a person. Lighter, more agile robots like Boston Dynamics’ Atlas are designed to fall safely without causing injury, a feature perfected through countless tests.

Strict Programming and AI Constraints.

Robot behavior is governed by carefully written code and AI models. Engineers use formal verification methods to mathematically prove that a robot’s software will behave as expected and won’t violate safety protocols. AI algorithms are also being developed with “safe exploration” constraints, which means the robot will not learn behaviors that could lead to dangerous outcomes.

The goal is to create a “digital fence” that the robot’s mind cannot cross.

Human Oversight and Remote Control: For many applications, especially those involving complex or public tasks, robots will operate under direct human supervision.

In a factory, a human operator can monitor several robots at once, ready to intervene if something goes wrong. For more advanced robots, teleoperation allows a human to take direct control of the robot in an emergency, or to guide it through a situation that it can’t handle on its own.

Ethical Guidelines and Regulation.

Beyond the technology, there’s a growing push for ethical guidelines and government regulation. Organizations like the IEEE are developing standards for autonomous systems, and governments are beginning to create laws around the use of robots in public spaces.

These regulations will likely require robots to be transparent about their capabilities and to be held accountable for their actions, much like we do with other technologies.

In conclusion, the control of robots is not being left to chance. The robotics industry is acutely aware of the risks and is building in multiple layers of safety from physical E-stops to sophisticated. AI constraints to ensure these machines can be reliable and trustworthy partners, not threats.

While the journey is far from over, the commitment to safety is a core principle in their design and deployment.

Have a Great Day!